.From: robert l nansteel

To: Gordon Raymer

Cc: Gus Elison

Sent: Saturday, February 23, 2002 6:52 PM

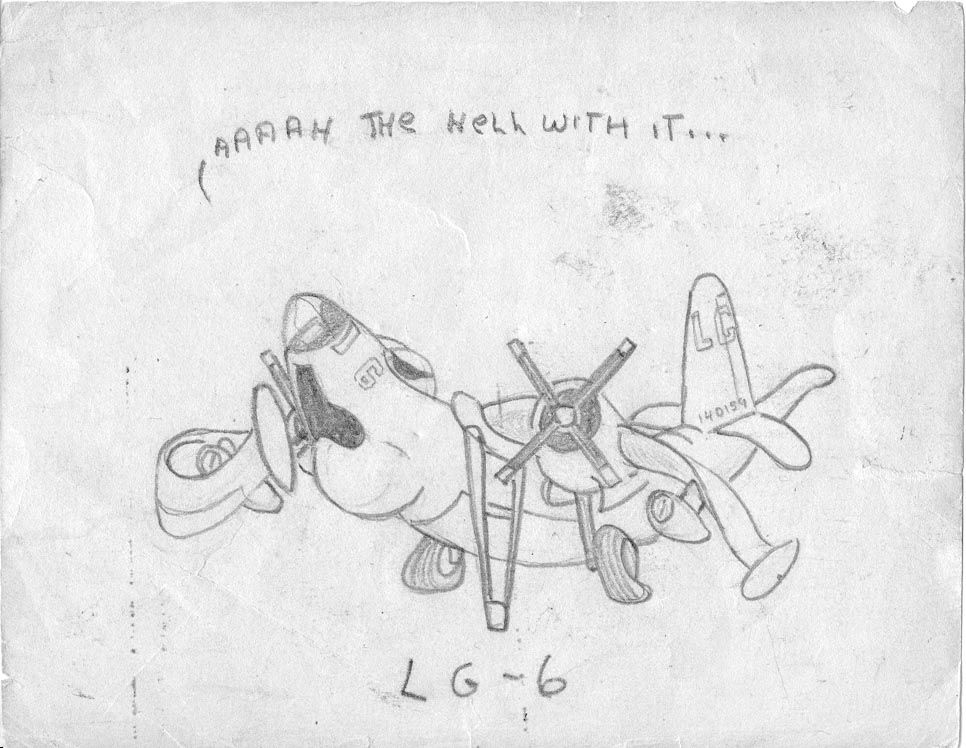

Subject: Crew # 6 Drawing

Hi :

Just wondered if this will loosen up some cob webs. I think ? Huth drew it

and we had it posted in the radio position during our deployment in '59--'60.

Ole # 6 may have been sick but we nursed her in fine shape, she was a

good old bird, Did everything we asked of her, kept an even number of T/O's

and landings, What more could one ask ??.

Bob

FROM Gerald McDonald....Once upon a time (October 21st, 1960 to be exact) a merry P2V-7 crew (Gerald McDonald, Dick Titus, Robert Nansteel, Billy Bell, and one or two others) was returning from a routine flight dedicated to training Dick. After having a few practice landings at an airport (cannot recall which one) in central Florida, Dick was making a practice GCA approach to runway 27 at NAS Jax. Just before intercepting the glide path Dick called out "Gear Down." Gerry moved the handle to the gear down position, turned to the right and saw the starboard gear was down. The next step of a dutiful co-pilot was to say, "I have one visual, three indicated, and is your gear down." Instead that report was interrupted and it became, "I have one visually and, Dick is your gear down." The port gear indicator was showing a 'barber pole.' He looked out the window and reported that it was not down, and in fact those wheel-well doors were still completely closed.

Needless to say, at this point Gerry notified GCA and Dick broke off the approach to start circling the field while we notified the Control Tower about the problem.

The next step was to move the landing gear handle to the Up position and after all three indicators showed the gear up to try lowering the gear again. That attempt resulted in an identical situation. From there it was on to the Flight Manual procedures for manually lowering the landing gear. (That was before NATOPS existed.)

Step 1: By-Pass the Hydraulic System.

Step 2: Pull the Johnson Bar in front of the wing beam to lower the main gear

Step 3: When the main gear is down and locked, pump the nose gear down.

Step 2 released the J-Hooks that held the gear up, and, supposedly, allowed gravity to lower the main Landing Gear. It worked fine on the starboard main gear, but had no effect on the port gear. The doors were still fully closed.

It was at that point that Gerry turned to Nansteel and said, "Nansteel, it is your damned airplane, FIX IT." His reply was aye, aye sir. But nothing he tried did any good. Then with the gear handle back to the up position, and all three gear in the wheel wells, we had no real idea how to get them all down.

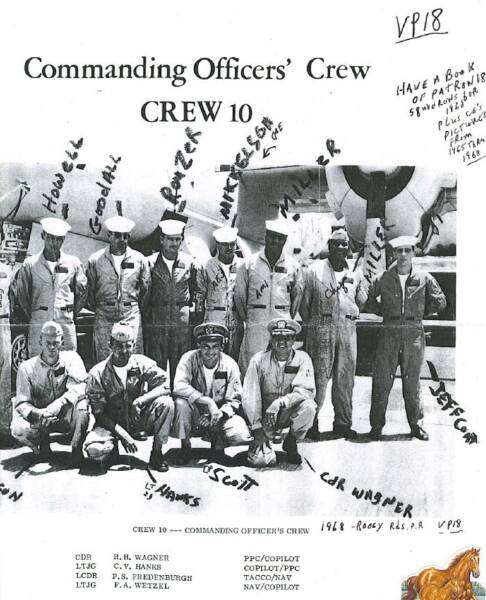

The Control Tower was asked to call the VP-18 Maintenance Office and advise them of problem. Shortly the tower called back to state, "Chief Nelson is on his way to the tower with maintenance manuals to give you a hand."

Together Nelson and Nansteel tried a number of different methods, all to no avail. By this time the sun was beginning to lower in the west and the fuel was getting a little low. People on the ground began to think about foaming the runway and called out the Crash Crew. Titus and Gerry discussed letting the crew bail out, but finally decided that it would be better if they rode the plane down to a belly-landing on the foam. (They were not qualified as paratroopers.)

In the meantime, Nelson and Nansteel came up with the idea of inserting a CO2 fire extinguisher into the Gear UP hydraulic line. Nansteel got rid of the hydraulic fluid at the selector valve, disconnected the landing gear-up line, and used a red, wipe-rag to take up the space between the CO2 nozzle and the line. Every time he triggered the fire bottle the crew could hear and feel landing gear jumping up to hit the rubber bumpers in the top of the wheel well. Never the less he kept triggering short burst of CO2 until the bottle was empty.

Nansteel then reconnected the hydraulic line, added fluid to the reservoir, and brought the hydraulic system back on line. That accomplished he returned to the cockpit and another was made at lowering the landing gear. Down went the handle and down came all three wheels. Chief Nelson was informed of the success, and a happy crew returned to the landing pattern with the wheel well doors flapping in the breeze. (Due to minor damage to the cables, sheaves, pulleys, etc that help control the doors.)

Unknown to the happy crew, a decision had already been made on the ground to start foaming the runway within the next ten minutes.

The landing was normal in all respects, however the aircraft was stopped on the runway, the brakes were set, and forward thrust was held on the engines to hold the main gear in place until the ground crew inserted safety pins in the landing gear struts.

Later examination by the maintenance crew found that one of the ¼ inch bolts that held the door pickup latch had sheared and wedged itself in the tracks that the landing gear used to close the doors when the landing gear came up. Apparently the safety wire on the broken bolt had failed and allowed the bolt to back out of position. That in turn allowed the landing gear to come too far up into the wells and shear the bolt. It in turn fell down into the tracks and jammed the doors in the closed position. Jarring the landing gear with CO2 had caused the bolt to fall out of the tracks, and it was jettisoned when the doors finally came open. Hence, there had not been a restriction in the hydraulic line.

Oh well! It was just another day at the office. VP-18's 30,000+-hour safety record was still intact, and everyone was happy, except the metalsmiths. They had to rebuild the landing door systems, but that was easier than rebuilding the belly of P2V-7 BuNo 147955.

New Subject: 148362 was not the last production plane off of the P2V-7 assembly line. I know for certain that Lockheed sold at least five later aircraft to the Netherlands Navy. Sometime before leaving VP-18 I briefed their first ferry crew on a route, and how to navigate across the Atlantic from Jacksonville to Holland.